Every homebrewer has their own unique perspective on the hobby. Different reasons of why you got into the hobby, different parts of it that bring you joy, different parts you hate, and different things you want to get out of it. Some people started in homebrewing because they just wanted to make something of their own, and as long as it’s homemade, they don’t sweat the details. Some find joy in building their own mega-system, customized to their own design and made up of bits procured from homebrew shops, hardware stores, and obscure hobby websites. Others are just into developing the perfect recipe they’ve got trapped up in their head. The list can go on and on.

When I first saw all-in-one brewing systems in the LHBS, I scoffed and said, “Who’d want to brew in one of those? It takes all the fun out of it.” The guy working replied, “Well, unless your joy comes from the recipe creation process and working to perfect your recipes.” I was skeptical, but it did get me thinking about what my personal joy of homebrewing was driven by.

I started my homebrewing life probably similar to many. I was really into beer, and the idea of making a hobby out of it, made it sound more sophisticated than just sitting around and drinking it. It was fun, but the lackluster results left me struggling to justify why I should go through all the trouble just to make 2 cases of mediocre beer when the beer store was overflowing with great options. I plugged along in the love/hate relationship for several years with extract and partial mash brewing, never quite satisfied with the results. Before giving up on homebrewing altogether, I decided I’d give it one last shot and I invested in some all-grain equipment to see if it was all it was purported to be. It was a Eureka moment as the telltale extract sweetness was gone and I was enjoying the beer now and all the newfound control knobs to experiment with (grains, mash temperatures, process details, etc.).

So after the words from the LHBS about all-in-one systems bounced around in my head for a few months, I started to see some merit in them. While some of the systems were marketed to appeal to extract brewers in an attempt to make the all-grain process seem less scary, for me it wasn’t about that. I was already all-grain brewing and loving it. Or at least most of it. Two things that nag me are process repeatability/control, and the length of time of my brew day.

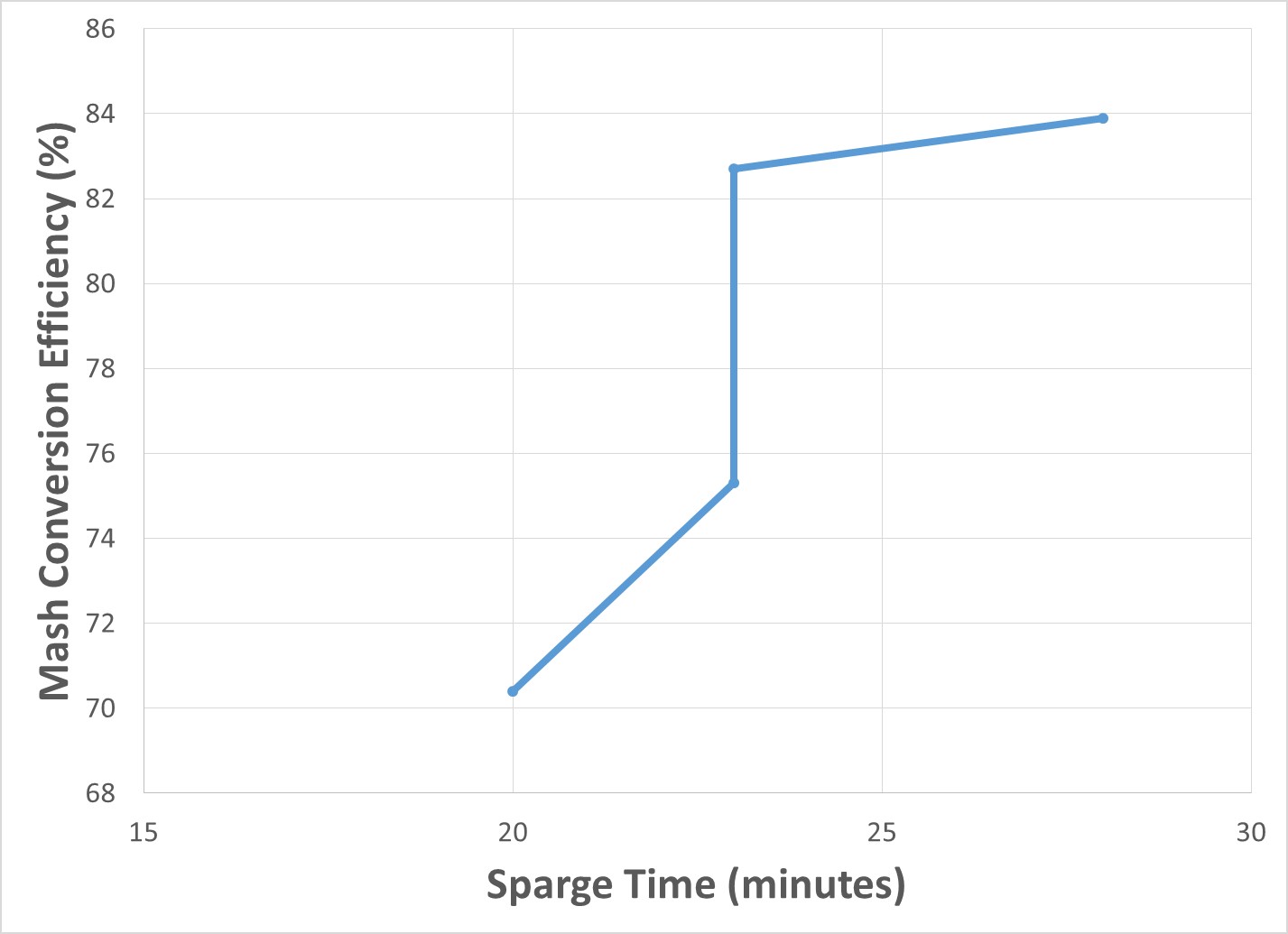

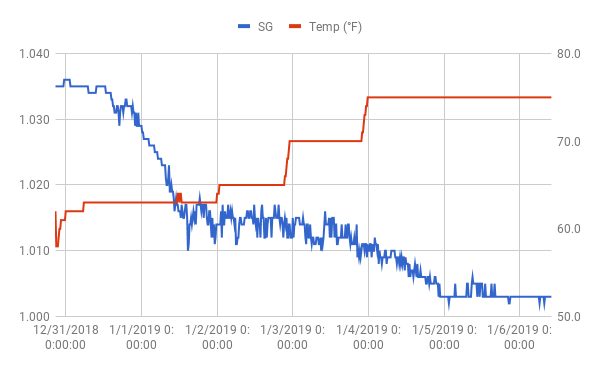

As an engineer, my whole brewing process is very detail-oriented. Starting from my recipe formulation on what exactly I’m trying to accomplish, what ingredients will best help me achieve that, and what aspects of the process I need to control. I write it all down in a detailed brew log notebook on brew day, and then I savor and analyze the results taking more notes on what I think worked, what didn’t, and what I should change next time. Here enters my 2 nagging problems. If I want to make that Pale Ale again, but tweak the malt flavor by modifying the grain bill, I want everything else to remain the same so I know if I was turning the right knob or if I should pursue some other change. But if I get largely varying mash efficiencies, or don’t have good control of mash temperature, I frequently find I’m changing more things than intended.

Everyone’s life has its own list of things that keep you busy. For me, it’s being married and having 2 young boys. So trying to carve out an 8 hour chunk of time for brew day can be a challenge, and that means I can’t brew as frequently as I want. So when I do get a brew day planned, it’s a fight between going back to that Pale Ale recipe to try out my tweak or making that Dusseldorf Alt that popped into my head 2 weeks ago and I can’t stop thinking about it. If a ‘Brew Day’ could be morphed legitimately into a ‘Brew Afternoon’ or ‘Brew Night’, I’d have time to do both Pale Ale Version 2.0 and Dusseldorf Alt 1.0. In other words, I could develop my skills at brewing more quickly by being able to go back and really experience what the process and ingredient changes make in the finished beer. I’ve heard several people mention that it takes 3 attempts at brewing a given beer/recipe until you can get it dialed in at exactly where you want it. I definitely have had the same experience.

More to come on my experiments on HomeBrewTalk.com in the near future as I compare multiple systems.

Ask almost anyone about homebrewing, and the worst part is the cleaning. It seems like you easily spend 50% of your “brewing” time, cleaning stuff. And there are people I read about on homebrew forums that seem to take it to extreme. So I try to take a minimalist approach, just doing what seems to be efficient and absolutely necessary.

Ask almost anyone about homebrewing, and the worst part is the cleaning. It seems like you easily spend 50% of your “brewing” time, cleaning stuff. And there are people I read about on homebrew forums that seem to take it to extreme. So I try to take a minimalist approach, just doing what seems to be efficient and absolutely necessary.

When ordering grains online at the homebrew shop, you usually have the option of whether you want them bagged altogether or separately. It’s always better separately for a number of reasons:

When ordering grains online at the homebrew shop, you usually have the option of whether you want them bagged altogether or separately. It’s always better separately for a number of reasons: and the drain wasn’t clearing. I brought out the plunger, but it didn’t help. In the end I had to do what I was trying to avoid in the first place and scooped the grains out into a bag. But I also had a clogged sink as a bonus. I had hoped that after sitting overnight it might somehow magically clear but it didn’t. The next day I had to take the pipes off under the sink to clear them out and snake them a couple times before finally getting it to clear. Lesson well learned as to the limitations of the kitchen sink garbage disposal.

and the drain wasn’t clearing. I brought out the plunger, but it didn’t help. In the end I had to do what I was trying to avoid in the first place and scooped the grains out into a bag. But I also had a clogged sink as a bonus. I had hoped that after sitting overnight it might somehow magically clear but it didn’t. The next day I had to take the pipes off under the sink to clear them out and snake them a couple times before finally getting it to clear. Lesson well learned as to the limitations of the kitchen sink garbage disposal.