Since moving from my single-vessel eBIAB set-up to a 2-vessel system (one kettle is the mash tun, the other is my boil/heating kettle), I couldn’t hit my predicted OG. So I set out to do some experiments to determine how to improve my efficiency. None of these changes were anything I came up with on my own, just a collection of actions I read from others. I just wanted data to quantify the impact on my set-up. And I wanted to study the different processes with an eye on overall brew time.

EXPERIMENT SET-UP

7 lbs 2-row

1 lb Crystal 40L

0.5 lb White wheat

Mash @ 1.4 qt/lb for 60 minutes @ 150F

Water + brewing salts + acid added to 5.6 pH

Sparge water @ 168F

Target pre-boil volume 7.5 gallons

BASELINE RUN

My base process since going to the 2-vessel system was to do a 1.4 qt/lb mash in my Mash Tun (MT), and then transfer in all of my sparge water that was heating my Boil Kettle (BK) on top of the mash. I would then drain water off the mash over a 20 minute period back into the BK. I crush my own grain, with a gap setting of 34 mil.

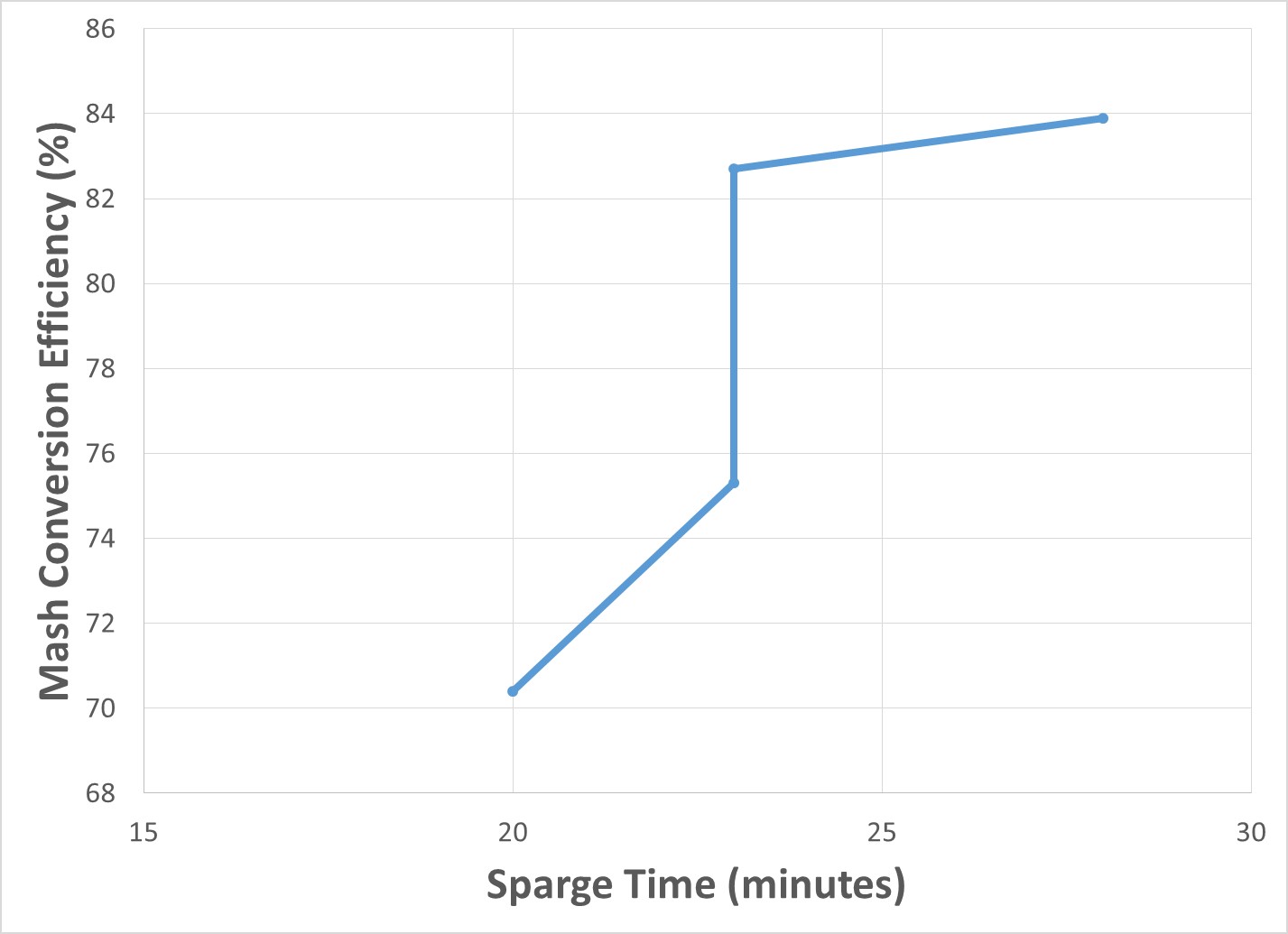

After mash was complete, it took me 20 minutes to collect the 7.5 gallons of wort into my BK. Conversion efficiency was calculated at 70.4%

RUN #2 (ADD SINGLE SPARGE STEP)

After the 1 hour mash, I’d run off all the wort in the MT into the BK. Then I’d fill the MT with the full sparge water volume, stir up the grains, then vourlaf until things became clear. After that, I’d transfer to the BK until I collected the 7.5 gallons of pre-boil wort.

It took me 23 minutes to collect the pre-boil volume. Conversion efficiency increased to 75.3%.

RUN#3 (SINGLE SPARGE WITH TIGHTER CRUSH)

Same process as Run#2, except this time I tightened the gap on my rollers down from 0.034″ to 0.026″.

For the same 23 minutes, conversion efficiency increased to 82.7%.

RUN#4 (20-MINUTE FLY SPARGE)

Same process as Run#3 with the 0.026″ crush, but instead of the single batch sparge, I did a 20-minute continuous fly sparge.

For an extra 5 minutes (28 minutes after the mash was done), conversion efficiency increased slightly to 83.9%.